Stay up to date on upcoming events, deadlines, news, and more by signing up for our newsletters!

Since establishing the Prototyping Fund in 2013, we have held two showcases per year, largely in person. The Spring and Fall of 2020 presented the first two opportunities to host the event in a virtual setting. In both cases, we were impressed by the teams’ resilience and ability to keep working on their prototypes (asking questions, building to testing, collecting feedback and iterating) despite the complex context of an unusual semester.

The Prototyping Fund is a collaborative program offered by the Design Lab @ NYU Tandon MakerSpace and the NYU Entrepreneurial Institute that provides teams of students mentorship and funding to build and test prototypes.

During the Fall showcase on Thursday, December 3, 9 teams (a mix of undergraduate, Master and Ph.D. students representing 6 NYU schools) from the Phase 1 cohort and 2 teams from Spring 2020 Phase 2 cohort joined on Zoom to present their prototypes (physical or digital), share their experiences and give feedback to each other. We also had a few visitors from the NYU Entrepreneurial Institute, NYU Tandon MakerSpace and Design Lab @ NYU MakerSpace and from NYU Tandon Department of Technology Management and Innovation and from Electrical Engineering. It was great for the teams to receive feedback and suggestions from experts in technology, prototyping and design; the comments shared during the event will help push their ideas forward.

As in previous years, multiple projects focused on sustainability and healthcare, while others created tools for musicians and support for mobile workers. Teams were creative in their presentation styles: from pictures, videos to live prototypes. Some teams like Fishel Aquaponics were extremely thorough in asking specific questions and addressing them through different prototypes. Others like Brian and Modular Workbook realized that building a prototype provided them a great prompt to engage with users and do more research.

Overall, the key insights were the importance of building prototypes to ask questions, of iterating (it was great to see many teams presenting the evolution of their prototypes over the semester) and developing use cases for a product or service (who are you designing for). We look forward to seeing how these different projects evolve.

Learn more about the Prototyping Fund Fall ‘20 projects and updates from the teams below:

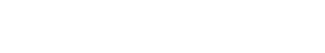

Augmented Reflections: explores how smart mirror interfaces can impact health behavior change. The prototype developed this fall featured an interface that displays real time stress levels with a responsive breathing exercise that is displayed when a threshold is reached.. Ayanna Seals, Tandon PhD ‘22

How we built it: To allow for safe user testing the prototype was a web application, that uses a web-camera to create the “mirror” effect and used react, socket.io, and d3 for the interface. A biosensor kit by Bitalino was used for modeling the stress sensor data format.

Top lesson learned: Not to re-create the wheel. The initial plan was to build a smart mirror, which would have left little time to focus on the interface and the integration of sensors. Prioritizing the interface also led to a prototype that can be user tested remotely online during the pandemic.

How can the NYU community help: I’d like to user test and experiment on how different interfaces impact health perceptions and behaviors. Anyone interested in participating can contact me: ayannaseals@nyu.edu. When in-person research is safe again I would like to have these interfaces displayed on an actual smart mirror. If anyone has experience creating them I’d love to chat.

Brian: The project is a sound-processing guitar, able to apply electronic effects controlled by an interface built into the body of the guitar itself. Ariane Schoenwiesner, Tandon BS '21

How we built it: Most of the woodwork was milled on the CNC routers in the MakerSpace, sanded down, glued together, clamped and left to dry. The sound effects processing was programmed into an Arduino with an FPGA.

Top lesson learned: Don't forget the maker community! There are plenty of guitar players eager to be able to modify their guitars, and willing to put in the work.

How can the NYU community help: I would love to have people to test the project, and to be able to talk with some UI developers who could help me make the modifications to the effects easier for any users who can't code.

Clean Surf: Surfboard made from recycled ocean plastics and other low environmental impact materials for a cleaner way to surf and ocean restoration. Cortlandt Meyerson, Gallatin BA ‘24 & Gregory Corn, Gallatin BA ‘24

Our team began this project by trying to create a surfboard out of ocean plastics, naming the project "Clean Surf". With cost in mind, we shaped the board out of recyclable XPS insulation foam planks that we combined with wood glue, embedded the board with collected plastic bottle caps to represent ocean plastics, and glassed the board with fiberglass and epoxy resin (which has much lower VOCs than its counterpart polyester resin). Unfortunately, an unexpected chemical fire occurred during the glassing process which is why the board looks incomplete (and like burnt toast). However, we were able to learn the skills of building a more environmentally-friendly surfboard and now know how to stop future prototypes from going up in flames.

E-Cube: A portable, bacteria-free, environment-friendly, electrical cube that can ice/heat drinks. YiQi Wu, Tandon MS ‘21; Jose Figueroa, Tandon MS ’21; Aaron Lee, SPS BA ‘24; Dahlia Milevsky, Tandon MS ‘22.

How we built it: We are using thermoelectic cooler to build the cube.

Top lesson learned: Due to E-Cube's tiny volume the power is not sufficient to cool or heat the water quickly. Heat dissipation is also a huge problem. We received user feedback regarding safety, go-to-market and general suggestions.

Fishel Aquaponics: is creating simple-to-use, humane, and beautiful indoor aquaponics kits that will allow customers to grow organic vegetables in the company of fishy friends. This past semester we built several work-like prototypes of our kits to experiment and optimize our design. E.W., GSAS MA ‘21 & E.J., GSAS MA ‘17.

How we built it: We used or modified plumbing equipment, brewing equipment, and/or commercial restaurant equipment to create aquaponics setups that tested different parameters.

Top lesson learned: We learned how to make our kits operate at a quiet, consistent sound level. We also determined the ideal level of water current for specific breeds of guppies and platies.

How can the NYU community help: If you're an indoor gardener or fish owner (or have aquaponics expertise you'd like to share), we'd love to chat with you to learn about what you value. Please email us at fishelkits@gmail.com.

Lymphedema Rehabilitation: A device for Lymphedema Rehabilitation that does the manual lymph drainage therapy. A donut-like device that will be worn over the affected arm or leg that will roll towards the upper side of the limb, putting pressure on the limb and moving lymph fluid away from fingers or toes. Manthan Pawar, Tandon MS ‘21

How we built it: The device went through a lot of design versions and prototype versions. The rapid 3d prototyping methodology was utilized to reach the final product.

Top lesson learned: Patients/user feedback is very important. Safety of the patient and therapist's approval for the prototype tastings and trials are paramount.

How can the NYU community help: NYU community can help me for user testing and feedback as well as making connections to the Lymphedema patients.

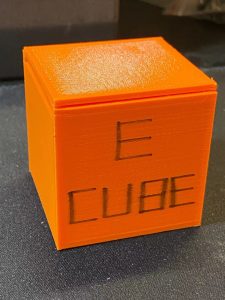

Modular Workbook: Designed a 3D printable shell to hold a tablet, Bluetooth keyboard, and touchpad to make being productive on the go more comfortable and accessible. The project is planned to be open source so the community can modify and remix it as they see fit for their personal devices. Jonathan Phan, Tandon MS ‘22.

How we built it: Using my 3D experience, I 3D modeled and printed several versions of my project and laser cut wooden panels.

Top lesson learned: Gained experience with the NYU Makerspace laser cutter and CNC machine. Also it is important to design for your target audience and not what you speculate people want.

Parkinson's Limb Rehabilitation Brace: A 3D printed brace built with sensors, to record muscle movement and "freezing moments" in Parkinson's patients. It establishes a baseline for when the patient experiences these symptoms in the context of their day-to-day life. Ameya Phadke, Tandon MS ‘21; Meet Doshi; Manthan Pawar Tandon MS ‘21; Sidhaant Gupta.

How we built it: We continually tweaked our design based on feedback from doctors, patients and therapists. We 3D printed a brace and attached our muscle sensor array and added a function to monitor and collate data from the sensors.

Top lesson learned: A venture, however small or big, cannot succeed without partnerships. We talked to a lot of relevant people that helped us focus our efforts and prioritize.

How can the NYU community help: We are planning to update our design followed by a test round with patients. Access to better materials would be a big time saver.

Proximity: Proximity is developing a new advertisement platform, we seek to build communities by partnering with transportation companies and businesses alongside their routes. We use screens on delivery trucks to display relevant ads to promote brands.We seek to disrupt high exposure static ad platforms such as billboards by using IoT technologies as a way to strategize brands ad-exposure through geofencing while not infringing with people’s online privacy. Our main drive comes from building a new way to connect people and their cities, by using screens on last-mile delivery trucks to create engagement for smart cities. Margarita Coronel, Courant MS '22. Neyl Loukil-Borras, Stern BA '22. Madeleine Mai, Tandon BS '23

How we built it: First, we used a Raspberry Pi, CPU component and connected a GPS module and antenna to enhance our ability to transfer real time data. In this case we were focusing on getting the right coordinates and updates of the location as we moved each unit. Second, we created geofences and assigned images to the selected points in the grid where we wanted them to show up. Third, we started testing by going to the chosen locations and confirming that the programmed image shows up within the assigned square on the grid.

Top lesson learned: For this prototype we focused on the feasibility of the technology, which involved setting up geofences and adding anchor points and images to those geofences. The most challenging part was to make the code more robust, in terms of being able to show an image while the GPS looks for a fix (coordinates). Now, we are able to print the GPS information and use those coordinates as triggers to display data points and images. Through testing, we learned that we are likely to find error messages when the unit goes out of bounds. We also learned that the consistent change of GPS coordinates impacts the show time of each image.

How can the NYU community help: Moving forward, we are looking to make progress in our code in order to improve ad performance. We will achieve this through testing and the development of new features. We encouraged students interested in IoT technologies to reach out for a hands on experience. Students in the marketing/advertising space are also welcome to reach out, your insight is key for the development of this new platform. As we go by our testing of the platform, the proximity team would like to promote NYU startups mkt campaigns on our screens. So for the new NYU ventures, feel free to reach out to us to promote your brand/idea.

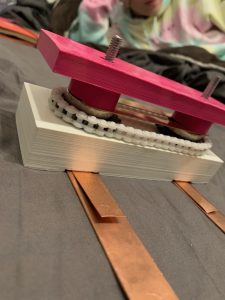

Walkway: Walkway is thin, above-ground generator that converts kinetic energy from footsteps into electricity. Ben Zhu, CAS BA ’23 & Max Trop, Tandon BS ’23, and David Lee, Kelley School of Business at Indiana University BA'23

How we built it: We used high performance, neodymium magnets and attached metal rods and copper plates to act as bridges between our dynamo setup with a joule thief circuit attached in order to get the most power. We then used a specialized, durable plastic chain to attach it mechanically so that only one would have to be driven while also having an encased ETP copper belt on the outer rims for the highest rpms on our device and to reduce resistivity by brush connectivity in relation to the high contact speeds.

Top lesson learned: Simplicity is king and vital for making our generator create the most electricity per dollar spent in manufacturing.

How can the NYU community help: Besides continuing to support the growth of the renewable energy sector, helping us connect with researchers at the University of Texas, Austin who have done research projects similar to what we are doing will help us learn more about this unconventional form of electrical generation and also if anyone with a background in electrical engineering is willing to intern for us, please contact us and we'll be more than happy to work with you!

Originally published on the Tandon MakerSpace blog.