NYU student entrepreneurs Dakota Marin, BS '18, Xikun Yuan, BS '19 and Roshaun Morris, BS/MS '19, from the Tandon School of Engineering, are the founders of Filaspool: Filament Maker. They are one of the eight teams who was awarded the NYU Prototyping Fund Phase 1 and Phase 2 grants. The objectives of Prototyping Fund is to provide student teams with the support and resources necessary to build prototypes, help articulate and/or move to the next stage of product development and encourage multidisciplinary collaboration between students at NYU.

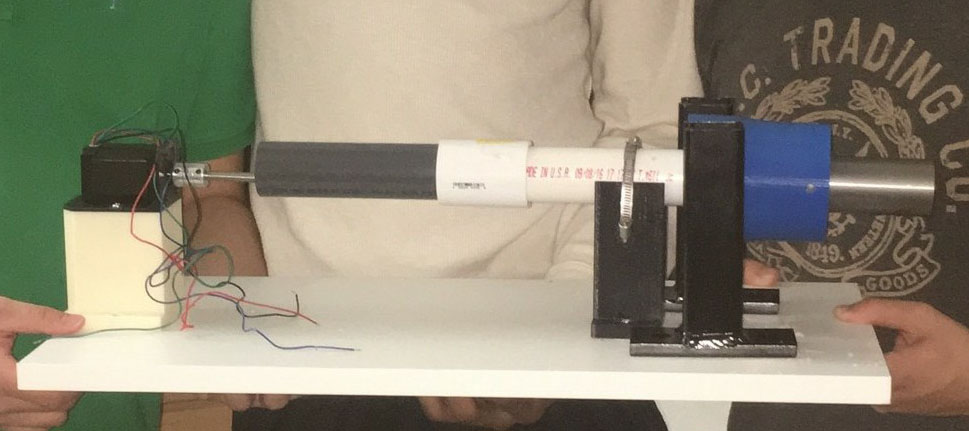

Filaspool is about helping tinkerers save money on a filament, for Desktop FDM 3D printers, by using recycled plastic bottles and failed 3D printed parts. It works by placing shredded plastic into a heating chamber, as a motor pushes the mottled pieces through a small hole, creating a thin string of filament ready to use. The problem our machine is combating is helping 3D printing enthusiasts save money on prototypes, by turning recycled plastic bottles and failed prints into filament. This not only saves money on failed prints, it also combats the waste issue we have in the world. Our prototype is composed of mainly PVC pipes, 3D printed couplings, a stepper motor, and two machined cylinders.

Phase 1 was testing our assumptions on how we could develop our product differently from competitors by finding out what works best. We couldn’t fully complete our prototype in Phase 1 because we underestimated the cost and challenges of building it, and ran into many obstacles. However, in Phase 2, we properly devised solutions for issues that emerged in Phase 1. We created a CAD model of the prototype and then a list of materials to see what we needed and how much it would cost. Because we learned from our previous mistakes, we ran successful tests.

Phase 1 was testing our assumptions on how we could develop our product differently from competitors by finding out what works best. We couldn’t fully complete our prototype in Phase 1 because we underestimated the cost and challenges of building it, and ran into many obstacles. However, in Phase 2, we properly devised solutions for issues that emerged in Phase 1. We created a CAD model of the prototype and then a list of materials to see what we needed and how much it would cost. Because we learned from our previous mistakes, we ran successful tests.

Plans we had for Phase 2 involved making sure our machine can create filament from plastic pellets and bottles, without going over budget. In addition to this, we also contacted potential customers and gathered information that would be necessary for improving our design.

We each utilized the backgrounds we have as engineering students. Roshaun and Dakota handled designing and making the machine from ordered, as well as 3D printed, parts. Xikun assembled the circuits and programmed the Arduino. However, when it came down to the business aspect of it, we collaborated on finding our customer base and created different business modeled canvases to see what would be the best path for us to take.

A benefit for participating in the NYU Prototyping Fund is creating a prototype of something you have in mind that can be game changing, for free! In addition to this, the support provided was crucial in allowing us to morph a concept we thought of into reality.